WorkBench is a lightweight application with a user-friendly interface. It was designed to smooth the learning curve for SMEs using ProjStream software, empowering them to input more data into BOEMax and MaxTeam more quickly.

This reduces the time required to collect data from a disparate mix of users and lowers the overall project costs.

WorkBench

makes data entry in BOEMax and MaxTeam a breeze.

What It Is

Simplify Data Entry with WorkBench

Save Time

Get your team started with ProjStream and have your project up and running in no time

Reduce Costs

Maximize your ROI on the ProjStream platform by leveraging its full functionality from the get-go.

Improve Data Quality

Reduce the risk of errors, inconsistencies and information gaps by providing SMEs with a simplified framework to enter their data.

How It Works

Configure the View Settings

WorkBench comes with built-in access controls allowing SMEs to only view their personal tasks. This way, they can direct all their attention to the work at hand.

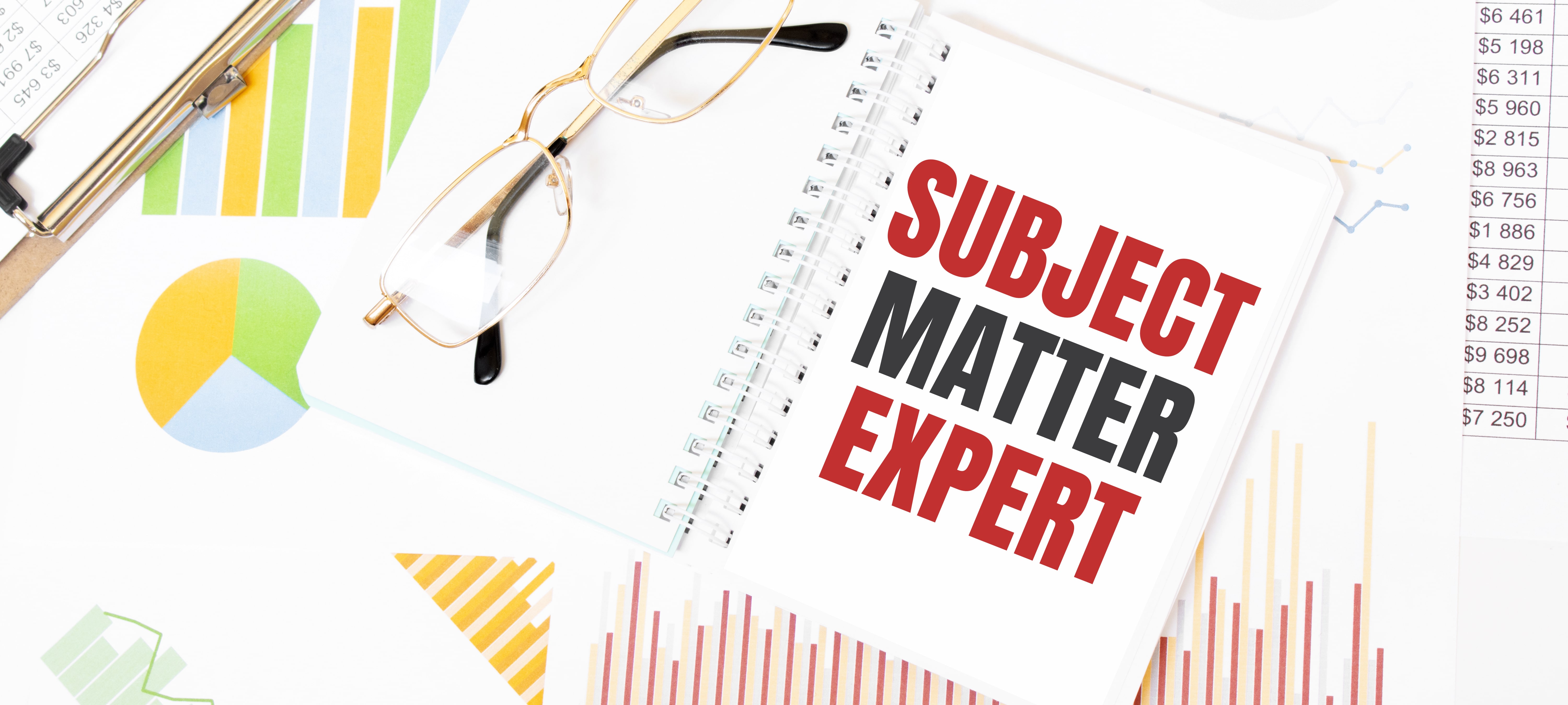

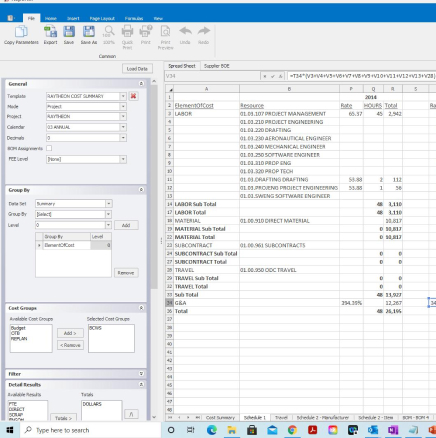

Enter Data in BOEMax

If using BOEMax, SMEs can enter both cost estimate data and BOE narrative text. They can also populate the BOM for their work element with source data available in the master parts and assemblies list.

This makes the job of the proposal manager easier, as they now have all SME data in a central database and can proceed with pricing the cost estimate — no “data wrangling” required. If needed, they can also use the source data in BOEMax to produce proposal schedule data. This saves time and ensures traceability between schedule and cost data.

Enter Data in MaxTeam

Both SMEs and control account managers can use WorkBench to enter the budget data at project startup. Throughout the execution phase, they can input estimate to complete and progress data as soon as work begins on a given work package – and MaxTeam automatically calculates the earned value for the reporting period. Variance analysis report (VAR) formats are provided in the CAM toolbox where the VAR writeup can be completed and routed for signature authorization. Progress entry and forecast data can also be routed for signature authorization, depending on what your process requires.

WorkBench offers a simple, easy, and organized way to route the right data to the right CAM or SME, adding efficiency and traceability to the process. Budget change requests can be modeled and routed via workflow, and when the budget change is made the work authorization document can be routed as well. The performance analysis process can be easily tailored to fit your process - WorkBench can easily align with the way your company does business.

3 Business Issues BOEMax Solves

Lack of Access to Historical Data

Teams often lack quick and reliable access to historical data like estimates, actual costs and BOMs. These are either unavailable or scattered across spreadsheets and legacy systems. This hurts both cost estimate quality and profit margins.

BOEMax stores all historical data in one easy-to-access repository. Proposal teams have all the information they need to create accurate and realistic BOEs at their fingertips, which reduces cost growth risk after contract award.

Inability to Verify BOEs

From BOE rationales to calculation methodology, quantifiable backup data is often unavailable with existing solutions. This makes it hard for third parties to verify BOEs and forces teams to rely on engineering judgment rather than source data, producing unrealistic proposals.

BOEMax allows you to create cost estimate templates, input BOE rationale and risks, enter assumptions text and attach related documents, all in the same place. Teams can build realistic estimates using a consistent methodology, and third-party verification becomes a breeze.

Proposals Take Too Long to Complete

The time it takes to build proposals from scratch using ad-hoc solutions, one-off Excel files and disjointed legacy systems limits companies’ ability to respond to RFPs. This is often due to a lack of a central database and an inability to share and manage data between team members.

With BOEMax, you can build a central data repository plus built-in templates and workflows. Teams can share data, collaborate, allocate tasks and track progress in real time. This improves proposal quality and reduces time to bid, allowing you to respond to more RFPs per year.